|

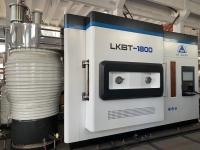

PVD Necklace Color Metallizing Machine

Collect

商品说明

Advantages: • PVD coatings are sometimes harder and more corrosion resistant than coatings applied by the electroplating process. Most coatings have high temperature and good impact strength, excellent abrasion resistance and are so durable that protective topcoats are almost never necessary. • Ability to utilize virtually any type of inorganic and some organic coating materials on an equally diverse group of substrates and surfaces using a wide variety of finishes. • More environmentally friendly than traditional coating processes such as electroplating and painting. • More than one technique can be used to deposit a given film.

Our vacuum coating equipment have acquired the TUV certification

Fine Finshed Sample

We can also finish to coat: Bright and firm finish Anti-corrosion and oxidation

pvd vacuum Ion plating equipment by touch screen and PLC control, multi arc magnetron coating technology with computer, equipped with automatic shifting vacuum gauge, flow controller, bias power supply, automatic temperature control inverter arc power, side mounted type heating pipe, computer PID. In addition, widely used in plating titanium nitride, titanium carbide, zirconium nitride, chromium nitride and titanium, nickel, chromium, copper, gold and silver, is a multifunctional equipment decoration industry much needed. Ion film plating using the equipment, good wear resistance, high ionization rate, fast deposition speed, stable performance, color diversity. At present, can be plated film color is golden yellow, Coffee color, bronze, gray, black, blue, rose and seven color and so on, to have the film adhesion, the density, from the characteristics, complexity and color consistency and good and, due to the use of the process of coating is a physical method of up-to-date, no "three wastes" emissions, has shown strong vitality and market competitiveness.

Professional packaging for export in case damage duiring shiping On time delivery Wooden packing, Carton packing or customized

|